54 0131f00022 janitrol oem replacement furnace blower motor 1 2 hp 115 volt 105 00 105.

Trane xe80 furnace blower motor.

You should be able to find your trane xe80 reset button on the blower motor.

Fine tune your comfort while lowering noise levels with our variable speed blower or four speed blower motor.

En español live chat online.

Trane oil burners are time tested and proven to deliver long life and stretch your energy dollar.

To keep the blower motor.

The trane part is mot09053 also x70671687010.

Led flashing light flashes continuously when burner is on however when the burner shuts off the led light flashes 4 times at an interval.

Belts naturally wear out over time but their service life can be shortened by faulty bearing and sheaves.

I saved about 670 dollars.

The ge part number is 5kcp39hgs599s.

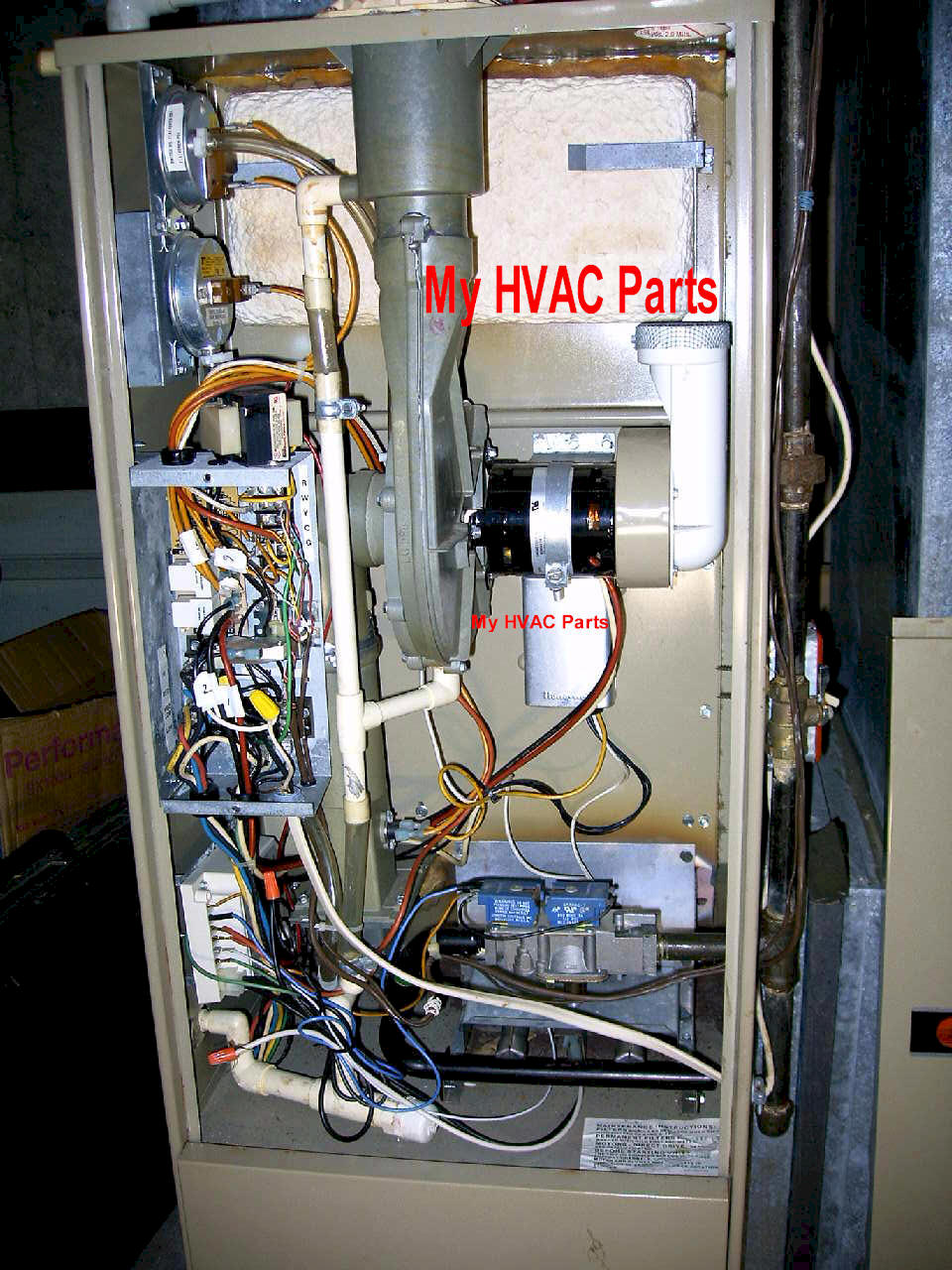

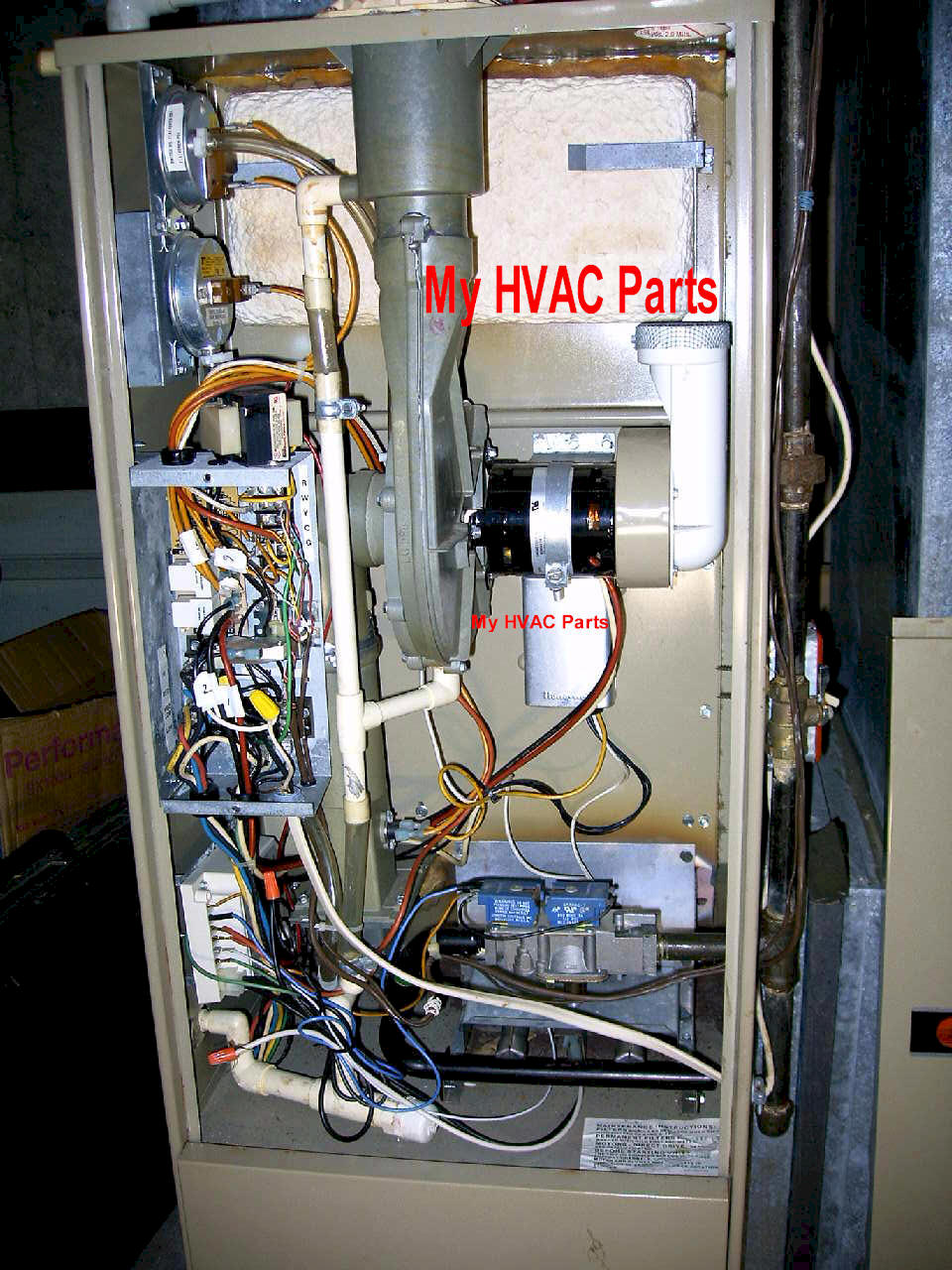

The motor ensures that air circulates through the furnace every time it comes on.

Motor uses a 5 uf 370 capacitor.

The blower motor is the heart of your trane xe80 gas furnace.

This is not a how to video so don t blame me if you electr.

Trane xe80 blower motors operate at a single speed will cost around 500 to replace.

Trane xe80 furnace reset button location.

Fast same day shipping.

The shaft is 1 2 diameter and 3 long if the shaft is facing up as seen in the picture rotation is clock wise.

365 day right part guaranteed return policy.

Brand new oem trane american standard ge genteq 4 speed furnace blower motor.

Trane furnace blower runs all the time.

It s 1 3 hp 115 volts and 1075 rpm.

This was my adventure of me dissecting and replacing my blower motor.

Every trane 80 oil furnace delivers an afue rating of up to 85.

Blower motor of trane xe80 furnace won t start the purge motor and burner go on but main motor won t run.

365 day right part guaranteed return policy.

Trane furnace blower not running.

Repair your trane furnace capacitor for less.

If the motor becomes too hot it can damage the furnace.

Repair your trane furnace motor for less.

The blower motor is usually one of the most reliable parts of trane xe80 furnace.

Routine motor preventive maintenance is essential for the air handler blower especially in belt drive units.

Belts that are slipping lose efficiency and a broken belt can result in unit downtime.